The roof load-bearing capacity is a crucial safety indicator of aluminum alloy tents, directly related to the safety of personnel and equipment inside, especially when used in complex weather conditions or with additional installations. Understanding this feature helps users select the right tent and use it safely.

Aluminum alloy tents’ roof load-bearing capacity is mainly determined by two key factors: the material of the aluminum alloy frame and the structural design. High-strength aluminum alloy materials, such as 6061-T6 aluminum alloy, are commonly used for tent frames. This material has excellent compressive and tensile strength, enabling the roof to withstand a certain amount of weight without deformation or collapse. In terms of structural design, most aluminum alloy tents adopt a truss structure for the roof. The truss design distributes the weight evenly across the entire frame, rather than concentrating it on a single point, which significantly enhances the overall load-bearing capacity of the roof.

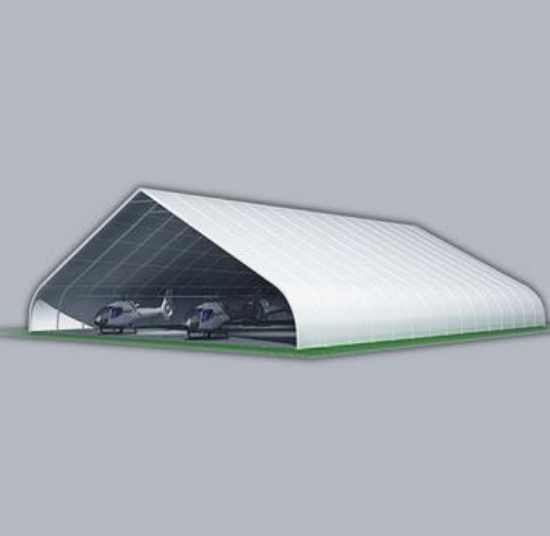

Different types of aluminum alloy tents have different roof load-bearing standards based on their sizes and application scenarios. Generally, small to medium-sized tents (with a span of less than 15 meters) have a roof static load-bearing capacity of 50-80 kg per square meter, which can easily bear the weight of small equipment like lighting fixtures and small speakers. Large-sized tents (with a span of more than 15 meters), designed for large-scale events such as exhibitions and concerts, have a higher roof load-bearing capacity, usually ranging from 80-150 kg per square meter. This allows them to accommodate heavier equipment, such as large audio systems and stage lighting racks.

It should be noted that the roof load-bearing capacity also needs to consider dynamic loads caused by external factors. For example, in rainy or snowy weather, the accumulation of rainwater or snow on the roof will increase the load. Therefore, many aluminum alloy tents are designed with a certain slope on the roof to facilitate the drainage of rainwater and the of snow, reducing the additional load on the roof. In areas with frequent heavy snowfall, users can also choose tents with enhanced roof load-bearing capacity or take preventive measures such as installing snow-melting devices.

To ensure the roof load-bearing capacity is not exceeded, users must follow the manufacturer’s specifications when using the tent. Do not arbitrarily add heavy objects to the roof beyond the specified load, and regularly inspect the roof frame and connections for signs of wear or looseness. By adhering to these guidelines, the aluminum alloy tent’s roof can maintain its stable load-bearing performance, providing a safe and reliable space for various outdoor activities.

Hi! Welcome back.

How are you doing?

+86 17712768856

NO.1319-1 Xicheng Rood Qingyang village, Jiangyin City,Jiangsu Province,China

Subscribe today and get educated and entertained with the monthly SYXTENT email